Technical PVD (Physical Vapor Deposition) is a process in which solid materials—such as titanium, chromium, or other hard metals—are vaporized in a vacuum environment and deposited as thin coatings on various surfaces. This technology enhances surface hardness, wear resistance, and performance in extreme conditions.

Fields of Application

Technical PVD is widely used across industrial sectors, including mechanics, aerospace, automotive, medical, electronics, and tooling.

Characteristics

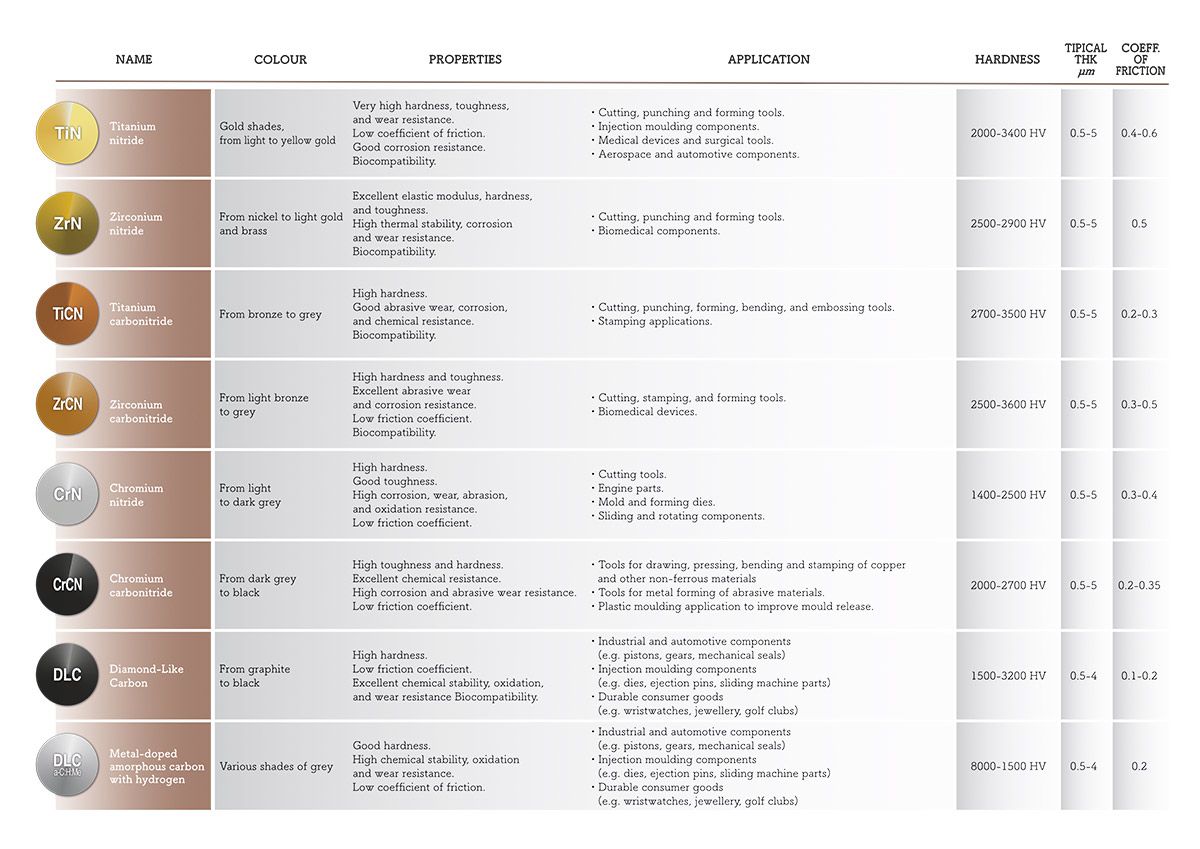

This coating technique produces ultra-thin layers with exceptional properties, such as:

Environmental Impact

Technical PVD is an eco-sustainable solution that avoids the use of toxic solvents and the production of hazardous waste. Compared to traditional treatments like hard chrome plating, it significantly reduces both environmental impact and energy consumption.

Technical PVD coatings are widely applied in industries such as mechanics, aerospace, and tooling. They form thin, durable layers that enhance the functional properties of treated surfaces, increasing their reliability and lifespan.

Technical PVD provides numerous benefits, making it ideal for both functional and aesthetic applications:

Performance Improvement:

Treated tools and components last longer, with increased resistance to wear and overheating.

Operational Efficiency:

Reduced friction improves productivity and decreases energy consumption in machinery.

Precision and Adaptability:

The coating can be applied to complex surfaces without altering dimensions or tolerances.

Cost Reduction:

Extended component lifespan reduces maintenance, repair, and replacement costs.

Eco-compatibility:

Replaces polluting chemical treatments, promoting environmental sustainability.

MK

900®

Compact and user-friendly design, delivering maximum productivity with just one operator.

MK

1400®

High automation for large-volume production, making it ideal for industrial production lines.

MK

1800®

Designed for maximum productivity in high-volume PVD coating applications.

This site uses cookies to improve the browsing experience of users and to gather information on the use of the site. We use both technical cookies and third-party cookies to statistically evaluate user behavior. You can know the details by consulting our privacy policy. Continuing browsing you accept the use of cookies; otherwise you can leave the site Cookie policy Privacy policy

Manage your cookie preferences below:

Essential cookies enable basic functions and are necessary for the proper function of the website.

Google reCAPTCHA helps protect websites from spam and abuse by verifying user interactions through challenges.

Google Tag Manager simplifies the management of marketing tags on your website without code changes.

Statistics cookies collect information anonymously. This information helps us understand how visitors use our website.

Google Analytics is a powerful tool that tracks and analyzes website traffic for informed marketing decisions.

Service URL: policies.google.com (opens in a new window)

You can find more information in our Cookie Policy and Privacy Policy.