Why the Market is Choosing Kolzer PVD 2.0

Kolzer PVD 2.0: the new era of vacuum coating that surpasses the limits of Arc technology.

Kolzer PVD 2.0: the new era of vacuum coating that surpasses the limits of Arc technology.

Kolzer Srl joins a team of established U.S. industry experts with a new U.S. base and a shared global vision.

In the jewelry industry, beauty, durability, and sustainability are essential to standing out in the market. With Kolzer PVD technology, you can offer jewelry with flawless finishes, superior longevity, and a more sustainable production process.

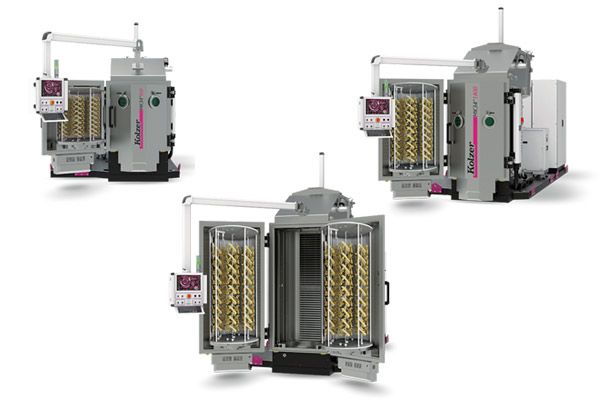

The MK34” machine is finally available in three load capacity variants, designed to adapt to different needs.

At Kolzer, we drive progress through innovation in PVD technology.

We have set up an on-site Coating Center for testing, equipped with the best existing preparation technologies…

Kolzer is aware of the challenges and opportunities that the market imposes and that rapid and successful decisions are needed to address them.

In the constantly evolving world of medical technology, the research of innovative solutions is crucial to improve the efficiency, reliability and safety of instruments and devices used in healthcare. In this context, physical vapor deposition (PVD) technology is rapidly proving to be one of the most prestigious techniques for coating medical devices, offering numerous advantages over traditional methods.

We are considered an eco-sustainable company and our machines are designed to reduce the consumption of harmful emissions, ensuring energy and water savings, while always remaining versatile and safe. Our processes do not produce waste and do not generate by-products.

Unlock unparalleled durability and enhanced performance with PVD (Physical Vapour Deposition) coating—an advanced surface treatment technology designed for a myriad of technical applications. PVD 2.0 coating by Kolzer is a cutting-edge process that revolutionizes the characteristics of various materials, offering superior hardness, wear resistance, and aesthetic appeal.

PVD (Physical Vapor Deposition) multicolor TiO2 (titanium dioxide) Iride is a thin film coating that is applied to surfaces using a vacuum deposition process. The result is a multicolored iridescent effect, similar to the colors seen in a rainbow, that is due to the interference and diffraction of light.

Thank you for your interest in original Kolzer products, to request information on the products and their availability/price you can write to [email protected]

– Have you found the material you need? Write to us at [email protected]

– Do you have questions? Write to us to get in touch with one of our expert team members. Write to us at [email protected]

– Can’t find the size or material you need? Please write to us at [email protected] and request the materials you are looking for.

This site uses cookies to improve the browsing experience of users and to gather information on the use of the site. We use both technical cookies and third-party cookies to statistically evaluate user behavior. You can know the details by consulting our privacy policy. Continuing browsing you accept the use of cookies; otherwise you can leave the site Cookie policy Privacy policy

Manage your cookie preferences below:

Essential cookies enable basic functions and are necessary for the proper function of the website.

Google reCAPTCHA helps protect websites from spam and abuse by verifying user interactions through challenges.

Google Tag Manager simplifies the management of marketing tags on your website without code changes.

Statistics cookies collect information anonymously. This information helps us understand how visitors use our website.

Google Analytics is a powerful tool that tracks and analyzes website traffic for informed marketing decisions.

Service URL: policies.google.com (opens in a new window)

You can find more information in our Cookie Policy and Privacy Policy.